What kind of company is CMK?

We have been producing printed circuit boards for 50 years.

CMK is a specialized manufacturer of printed circuit boards

with a strong presence in the automotive industry.

CMK at a glance

Establishment year

0

Experience for supplying automotive PCBs

Over0years

Number of employees (consolidated)

0

Number of employees with qualifications related to environmental laws and regulations

0

Figures are as of Sep. 30, 2023

Area coverd by annually manufactured PCBs

Approximately0million

square meters

Net sales

0billion yen

Percentage of net sales of automotive PCB

0%

Net sales

by geographical segment

Overseas

0billion yen

Japan

0billion yen

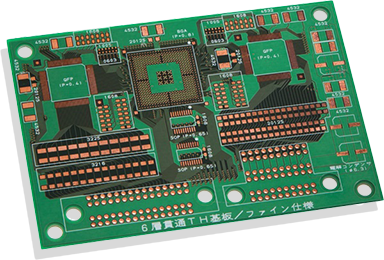

What are printed circuit boards?

Printed circuit boards (PCBs), also known as electronic circuit boards, are essential components found in various electronic devices that support our daily lives. The role of a printed circuit board is to serve as a foundation for mounting components and to establish electrical connections between them, allowing the transmission of electrical signals.

To draw an analogy, a printed circuit board functions as the skeletal and nervous system of the human body, playing a crucial role as the core device in electrical products.

Printed circuit boards play a vital role in various applications, bridging our lives and shaping the future.

Examples of places in which PCBs are used

Examples of places in which PCBs are used

-

In offices

In offices

Used in computers, multifunction printers, telephones and smartphones, teleconferencing equipment, projectors, etc.

-

In automobiles

In automobiles

Used in advanced driver-assistance systems such as dashboard camera, automatic braking systems, lane centering systems, millimeter-wave radar devices, digital camera sensors, infrared cameras, sonar monitoring units, etc.

-

In commercial facilities

In commercial facilities

Used in large video screens, digital signage, cash dispensers, ATMs, security cameras, etc.

-

In train stations

In train stations

Used in electronic noticeboards, automatic ticket machines, digital signage, security cameras, etc.

-

In homes

In homes

Used in televisions, air conditioners, smartphones, tablet PCs, video game consoles, smart appliances, smart meters, etc.

-

For fitness actvities

For fitness actvities

Small and thin circuit boards are also used in devices such as smartwatches and smart glasses, which feature communication capabilities and healthcare functions.

CMK's competitive advantages

- 01

- High-Quality and Reliable Manufacturing

-

- Our expertise lies in drivetrain and control systems, which require exceptional reliability in the automotive sector.

- Our automotive build-up printed circuit boards (HDI) hold the world's top market share.

- 02

- Responsiveness to Customer Needs

-

- Supported by our accumulated technology and experience, we offer strong analytical capabilities and rapid customer response.

- We provide a stable supply and warranty system for the long term, thanks to our solid financial foundation.

- We also collaborate on roadmaps with major automotive component manufacturers.

- 03

- Track Record

-

- Over 50 years of experience as a dedicated printed circuit board manufacturer.

- More than 30 years of expertise in automotive printed circuit boards.

Reliability and Technology Supporting Printed Circuit Boards

Our products are not only used in critical automotive components related to 'driving, steering, and braking' but also contribute significantly to a wide range of applications in environmental and infrastructure sectors, supporting safety, comfort, and the future development of society.

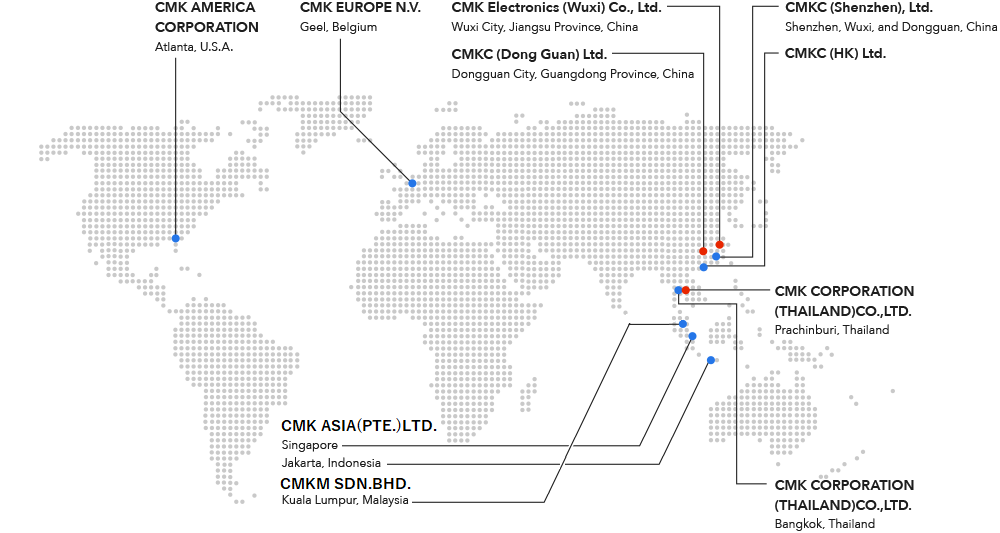

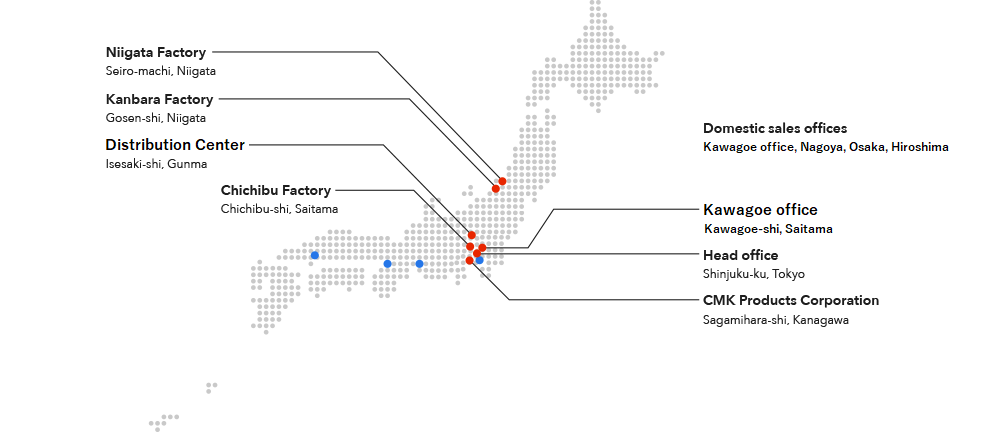

Striving for Global Standardization

The automotive printed circuit board market, which is a key focus for our company, continues to expand globally. This growth is driven by increasing sales of new vehicles, the rising demand for advanced driver assistance systems (ADAS) due to the expansion of preventive safety and driving support, and the spread of next-generation vehicles in response to stricter environmental regulations.

To meet the growing demand, our group is actively enhancing production capacity and improving productivity. The electrification trend in the automotive industry indicates that the demand for automotive printed circuit boards will continue to increase in the future.In response to these market conditions, we have decided to expand the factory of our subsidiary, CMK CORPORATION (THAILAND) CO., LTD., to strengthen our production capacity. This expansion in Thailand enables us to capture the growing global demand for automotive printed circuit boards and further expand our revenue.By striving for global standardization and expanding our manufacturing capabilities, we aim to solidify our position as a leading player in the automotive industry and maximize our growth potential.

Quality and Environmental Management System

To ensure consistent quality across products manufactured in our various facilities around the world, an effective system that guarantees the same high level of quality is crucial. For this reason, our group has obtained certifications for internationally recognized standards such as ISO 9001, ISO/TS 16949 (IATF 16949) for the automotive industry, and ISO 14001 for environmental management systems. These international standards serve as the basis for our internal management systems, allowing us to efficiently and effectively implement quality and environmental management. We are committed to the seamless integration and continuous improvement of our quality and environmental management systems.

Efforts towards Enhanced Quality for Consistent Global Standards

We prioritize safety and assurance in delivering products to our customers by conducting reliability evaluations at a higher standard, taking into consideration how the products are used in the market and the warranty period for each product specification. For products that do not meet our reliability evaluation criteria, we thoroughly investigate the root causes and provide feedback to the manufacturing teams, aiming for continuous improvement in quality.

In the analysis of issues or defects, we have integrated various analytical tools and equipment within our company to efficiently and accurately identify causes and implement countermeasures. This knowledge is shared across the group to ensure consistent product quality and enhance our commitment to quality improvement.