What is 'E-spec'?

At CMK, we supply products that meet our in-house environmental standards (called 'E-spec') and are committed to reducing environmental impact through our product offerings.

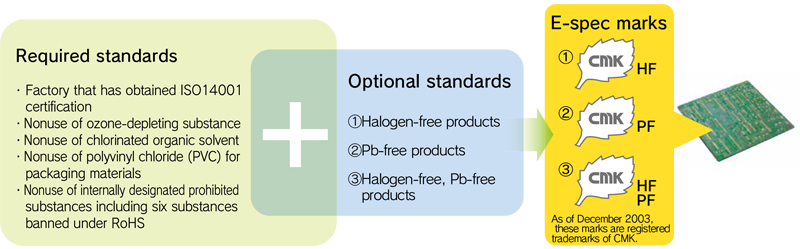

The E-spec Standard Concept

E-spec standards consist of both mandatory and optional criteria. Products that meet these standards display the E-spec mark upon request.

E-spec Specifications

1.Halogen-free products

| Chlorine Content | 0.09 wt% or less |

|---|---|

| Bromine Content | 0.09 wt% or less |

| Total Chlorine and Bromine Content | 0.15 wt% or less |

| FR-1 Grade | 0.15 wt% or less |

|---|---|

| CEM-3 Grade | 0.15 wt% or less |

| FR-4 Grade | 0.15 wt% or less |

By using substrates that meet the JPCA Halogen-free Standard, the halogen content is reduced to 1/60 (compared to conventional substrates).

2.Lead-free products

Heat resistance standard for lead-free compatible products* (reflow heat resistance)

| Name Grade | Peak temperature | Reflow temperature / time | Reflow cycles |

|---|---|---|---|

| CEM-3 | 250°C | 230°C or higher / 50±5 seconds | 2 |

| FR-4 | 260°C | 230°C or higher / 60±5 seconds | 2 |

Lead-free compatible surface treatment

| Surface treatment |

Wettability | Heat resistance |

Smoothness | Environmental impact |

Cost | Shelf life |

|---|---|---|---|---|---|---|

| Thermal resistant preflux / water-soluble | ○ | ○ | ◎ | ◎ | ○ | 3 months |

| Gold plating | ○ | ◎ | ◎ | ○ | △ | 6 months |

| Lead-free solder leveler (Sn-3Ag-0.5Cu) |

◎ | ◎ | × | ○ | × | 6 months |

Comparative analysis based on internal data and market research.

*In Japan, CMK Group phased out resin-based heat-resistant flux in January 2008 based on our plan to reduce the use of volatile organic compounds (VOCs).